- Time:2024/08/01 Posted:Dongguan Quality Innovation And Technology Co.,Ltd

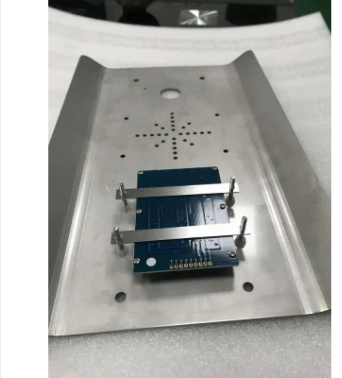

Elevator access control keypads are crucial components for ensuring secure and efficient building management. They need to withstand frequent use, environmental exposure, and potential tampering. When it comes to manufacturing these keypads, 304 stainless steel stands out as an ideal material due to its excellent properties and performance characteristics. This guide explores why 304 stainless steel metal stamping is a top choice for elevator access control keypads, highlighting its key benefits and providing solutions to common issues.

Key Benefits of 304 Stainless Steel Metal Stamping

1. Superior Durability and Strength

Benefit: 304 stainless steel is renowned for its excellent strength and durability. It can withstand heavy usage and physical stress without deforming or breaking.

Advantage: This durability ensures that elevator access control keypads remain functional and intact even in high-traffic areas, reducing the need for frequent replacements and maintenance.

2. Corrosion Resistance

Benefit: 304 stainless steel offers outstanding resistance to corrosion and rust, thanks to its high chromium and nickel content.

Advantage: This corrosion resistance is crucial for keypads exposed to various environmental conditions, including humidity, temperature fluctuations, and contact with cleaning agents. It ensures that the keypads maintain their appearance and functionality over time.

3. Aesthetic Appeal

Benefit: 304 stainless steel provides a sleek, modern appearance with a smooth, polished surface.

Advantage: The aesthetic appeal of stainless steel enhances the visual appeal of elevator keypads, contributing to a high-quality, professional look that complements modern building designs.

4. Ease of Maintenance

Benefit: The smooth surface of 304 stainless steel is easy to clean and maintain. It resists staining and can be wiped clean with standard cleaning agents.

Advantage: This ease of maintenance helps keep the keypads looking new and ensures hygienic operation, especially in high-traffic areas where cleanliness is essential.

5. Excellent Formability

Benefit: 304 stainless steel is highly formable, allowing for intricate designs and precise metal stamping.

Advantage: This formability enables the production of keypads with detailed features, such as raised buttons, engraved text, and custom shapes, while maintaining structural integrity.

6. Temperature Resistance

Benefit: 304 stainless steel performs well under a wide range of temperatures, from low to high heat.

Advantage: This temperature resistance ensures that the keypads function reliably in different environmental conditions, including both hot and cold climates.

Common Problems and Solutions

1. Surface Scratches and Marks

Problem: Despite its durability, 304 stainless steel can develop scratches or marks from handling or usage.

Solution:

- Protective Coatings: Apply protective coatings or finishes to reduce the likelihood of scratches and preserve the surface appearance.

- Regular Cleaning: Use non-abrasive cleaning agents and soft cloths to clean the surface and remove any marks without causing additional scratches.

- Preventive Measures: Implement handling procedures to minimize contact with sharp or rough surfaces during installation and maintenance.

2. Corrosion Under Extreme Conditions

Problem: While 304 stainless steel is highly resistant to corrosion, extreme conditions or exposure to harsh chemicals can lead to localized corrosion.

Solution:

- Material Selection: For environments with severe corrosive elements, consider upgrading to 316 stainless steel, which offers enhanced corrosion resistance.

- Protective Measures: Apply protective coatings or treatments to further enhance resistance to specific environmental factors.

- Regular Inspection: Conduct regular inspections to identify and address any signs of corrosion early.

3. Dimensional Inaccuracies

Problem: Dimensional inaccuracies can occur due to machine calibration issues or material inconsistencies during the stamping process.

Solution:

- Calibration: Regularly calibrate stamping machines and tools to ensure precision and accuracy in the production process.

- Quality Control: Implement strict quality control measures, including dimensional checks and testing, to ensure that parts meet specifications.

- Material Consistency: Verify material specifications and quality before processing to prevent inconsistencies.

4. Difficulty in Customization

Problem: Achieving intricate or customized designs can sometimes be challenging with metal stamping.

Solution:

- Advanced Stamping Techniques: Utilize advanced stamping techniques and machinery capable of handling complex designs and fine details.

- Design Collaboration: Work closely with manufacturers to develop and refine designs that can be effectively produced with 304 stainless steel.

- Prototype Testing: Create prototypes to test and validate custom designs before full-scale production.

5. Thermal Expansion Issues

Problem: Stainless steel can expand or contract with temperature changes, potentially affecting the fit or function of keypads.

Solution:

- Design Tolerances: Design keypads with appropriate tolerances to accommodate thermal expansion and contraction without affecting functionality.

- Material Selection: Choose materials with compatible thermal expansion properties to ensure that keypads perform reliably across varying temperatures.

- Temperature Testing: Conduct temperature testing to evaluate the impact of thermal changes on the keypad’s performance and make necessary adjustments.

6. High Production Costs

Problem: The cost of producing high-quality 304 stainless steel keypads can be relatively high due to material and manufacturing expenses.

Solution:

- Optimize Design: Optimize the design to reduce material waste and production complexity, helping to lower overall costs.

- Batch Production: Consider batch production or bulk manufacturing to take advantage of economies of scale and reduce per-unit costs.

- Supplier Negotiation: Work with suppliers to negotiate pricing and explore cost-saving options without compromising quality.

Conclusion

304 stainless steel metal stamping offers numerous benefits for elevator access control keypads, including superior durability, corrosion resistance, and aesthetic appeal. By addressing common problems such as surface scratches, corrosion under extreme conditions, and dimensional inaccuracies, you can ensure the production of high-quality, reliable keypads that meet performance standards. Implementing proper quality control, material selection, and design considerations will help you maximize the advantages of 304 stainless steel and achieve optimal results. For specific troubleshooting support or advanced issues, consult with manufacturers and technical experts to ensure the best performance and quality for your elevator access control keypads.