- Time:2024/08/30 Posted:Dongguan Quality Innovation And Technology Co.,Ltd

Applications of Die-Cast Aluminum Alloy Castings in Automobiles: A Comprehensive Overview

Die-cast aluminum alloy castings have become an integral part of modern automobile manufacturing, offering a blend of durability, lightweight properties, and cost-effectiveness. As the automotive industry pushes towards more fuel-efficient and eco-friendly vehicles, the demand for these components continues to rise. This blog will explore the key applications of die-cast aluminum alloy castings in automobiles, highlighting their benefits and addressing common issues.

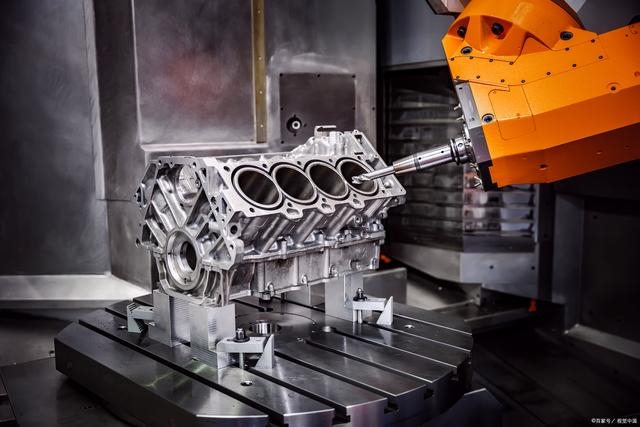

1. Engine Components

One of the most critical applications of die-cast aluminum in automobiles is in the production of engine components. Parts like cylinder heads, engine blocks, and pistons are commonly made from aluminum alloys due to their excellent thermal conductivity and lightweight nature. These qualities help improve engine efficiency and performance while reducing overall vehicle weight.

Benefits:

- Improved Fuel Efficiency: Lighter engine components lead to reduced vehicle weight, which in turn enhances fuel efficiency.

- Enhanced Heat Dissipation: Aluminum's high thermal conductivity ensures that heat generated by the engine is efficiently dissipated, preventing overheating.

Common Issues and Solutions:

- Thermal Expansion: Aluminum can expand under high temperatures, potentially causing engine parts to fit less tightly. Regular maintenance and the use of advanced alloy compositions can mitigate this issue.

2. Transmission Housings

Die-cast aluminum alloy castings are also widely used in transmission housings. These housings protect the transmission system while allowing it to operate smoothly. The lightweight nature of aluminum contributes to a reduction in overall vehicle weight, which is crucial for achieving better fuel economy.

Benefits:

- Weight Reduction: Aluminum housings significantly reduce the weight of the transmission system, contributing to overall vehicle efficiency.

- Corrosion Resistance: Aluminum’s natural resistance to corrosion ensures that transmission housings remain durable over the lifespan of the vehicle.

Common Issues and Solutions:

- Surface Imperfections: Die-cast aluminum can sometimes develop surface imperfections that might affect the housing's integrity. Employing advanced casting techniques and post-casting treatments can address this problem.

3. Wheels and Rims

Aluminum alloy wheels and rims are popular in the automotive industry due to their aesthetic appeal and performance benefits. They are not only lighter than steel alternatives but also provide better heat dissipation, which is essential for maintaining tire performance and longevity.

Benefits:

- Enhanced Aesthetics: Aluminum wheels can be molded into intricate designs, offering a sleek and modern appearance.

- Improved Handling: The reduced unsprung weight from aluminum wheels contributes to better vehicle handling and ride comfort.

Common Issues and Solutions:

- Cracking and Bending: Aluminum wheels are more prone to cracking or bending upon impact compared to steel. Regular inspections and opting for higher-grade alloys can help prevent these issues.

4. Suspension Components

In modern vehicles, die-cast aluminum is increasingly used in suspension components such as control arms, knuckles, and subframes. The lightweight and strong nature of aluminum helps enhance the vehicle's handling and reduces the strain on suspension systems.

Benefits:

- Better Handling: The reduced weight of aluminum suspension components lowers the vehicle's center of gravity, leading to improved handling and stability.

- Longevity: Aluminum’s resistance to rust and corrosion extends the lifespan of suspension components.

Common Issues and Solutions:

- Fatigue Failure: Repeated stress on aluminum components can lead to fatigue failure over time. Regular inspections and using high-quality alloys can mitigate this risk.

5. Body Panels

Aluminum alloy castings are increasingly being used in body panels, including doors, hoods, and trunk lids. The lightweight nature of aluminum contributes to overall vehicle weight reduction, which is crucial for meeting stringent fuel efficiency standards.

Benefits:

- Fuel Efficiency: Lighter body panels contribute directly to improved fuel economy.

- Crash Performance: Aluminum panels can be designed to absorb energy in a crash, enhancing vehicle safety.

Common Issues and Solutions:

- Denting: Aluminum panels can be more susceptible to dents than steel. Using thicker panels and reinforcing critical areas can help reduce this problem.

Conclusion

Die-cast aluminum alloy castings are revolutionizing the automotive industry by offering lightweight, durable, and cost-effective solutions for various vehicle components. From engine parts to body panels, the applications of aluminum are vast and growing. While there are some challenges associated with using aluminum, such as thermal expansion and fatigue failure, advancements in materials science and manufacturing techniques continue to address these issues. As the automotive industry evolves, the role of die-cast aluminum alloy castings is set to expand, driving innovation and efficiency in vehicle design.