- Time:2024/09/26 Posted:Dongguan Quality Innovation And Technology Co.,Ltd

In the world of modern manufacturing, CNC lathes have become essential tools for delivering highly accurate and efficient machining processes. With their ability to automate and precisely control cutting, shaping, and drilling, CNC lathes have revolutionized industries ranging from automotive to aerospace and beyond. Whether producing intricate components or high-volume runs, these machines represent the pinnacle of precision engineering.

This article dives into the key features that make CNC lathes a vital part of modern production, and how they combine speed, accuracy, and versatility to meet the demands of today’s fast-paced industries.

1. What Are CNC Lathes?

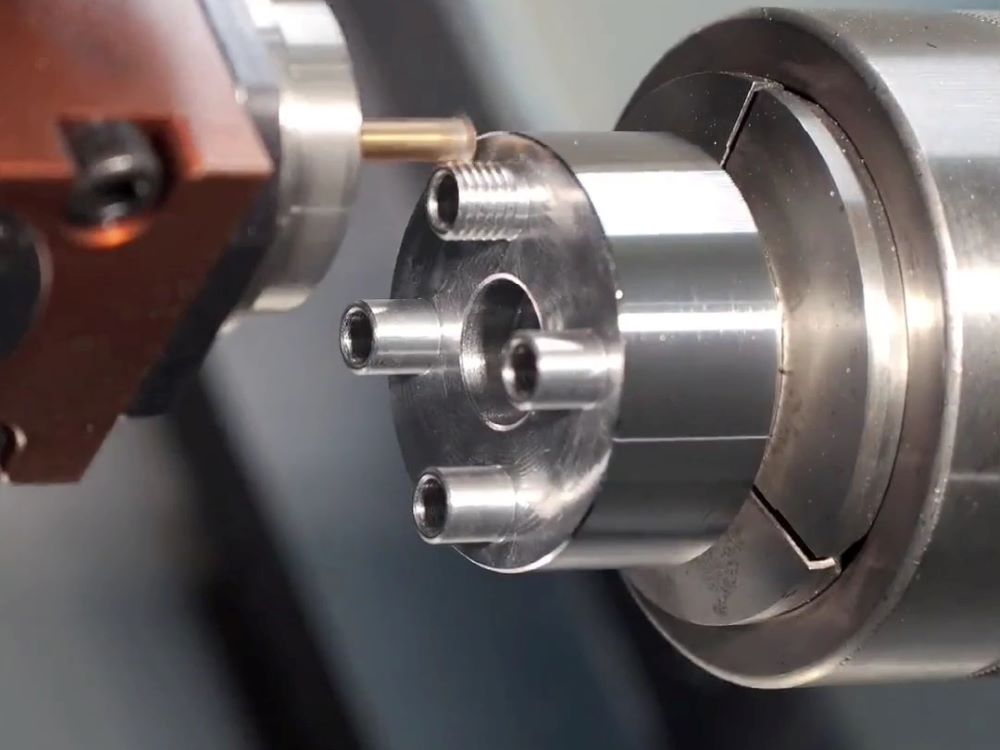

A CNC lathe is a sophisticated machining tool controlled by computer numerical control (CNC). Unlike traditional lathes, which rely on manual operation, CNC lathes use software programs to manage and automate the cutting process. The machine’s movements and operations are pre-programmed, allowing for greater precision and the ability to perform complex tasks with minimal human intervention.

The lathe rotates the material (often metal or plastic) along a horizontal axis, while cutting tools shape and modify the piece as it spins. This process is ideal for producing symmetrical parts like cylinders, shafts, and cones. CNC lathes handle everything from simple cuts to intricate patterns, ensuring accuracy down to the smallest detail.

2. Unparalleled Precision and Accuracy

One of the standout features of CNC lathes is their ability to achieve extremely tight tolerances. Whether creating aerospace components or medical devices, precision is paramount, and CNC lathes consistently deliver it. These machines use advanced sensors and precise programming to produce parts with micron-level accuracy, ensuring every product meets exact specifications.

The use of computer software ensures that even the most intricate designs can be produced without error, eliminating the variations that can occur with manual operations. Whether you're working with delicate materials or hard metals, CNC lathes provide reliable consistency and repeatability.

3. High Efficiency and Automation

In today’s fast-paced manufacturing environment, speed is just as critical as precision. CNC lathes excel in both areas, offering high-speed cutting and automated production that increases output while maintaining quality. Once programmed, the machine can run autonomously, allowing for 24/7 operation with minimal oversight. This reduces downtime and increases overall production capacity.

Additionally, CNC lathes can be programmed to perform multiple operations on a single part without needing to stop or reconfigure the machine, saving time and labor costs. From turning and drilling to threading and knurling, these machines handle a variety of tasks in a single setup.

4. Versatility Across Materials and Industries

Another remarkable feature of CNC lathes is their versatility. These machines can work with a wide range of materials, including metals (steel, aluminum, titanium), plastics, and composites. This versatility makes CNC lathes ideal for a diverse array of industries:

Automotive: CNC lathes are commonly used to produce engine components, transmission parts, and other critical automotive elements.

Aerospace: In aerospace, precision is key. CNC lathes produce parts such as turbine blades, landing gear, and flight-critical components.

Medical Devices: CNC lathes are used to create surgical instruments, prosthetics, and complex medical implants with exacting standards.

Electronics: Small components like connectors, housings, and heat sinks are frequently produced using CNC lathe technology.

No matter the material or application, CNC lathes provide customization and adaptability to meet the unique needs of any industry.

5. Advanced Control and Customization

One of the most important features of CNC lathes is the ability to customize operations through programmable controls. Using CAD/CAM software, manufacturers can design and simulate parts before they are produced. Once the design is finalized, the program is uploaded to the lathe, where it directs every movement and cut with pinpoint accuracy.

CNC lathes are also capable of multi-axis machining, which allows for more complex geometries to be manufactured in a single setup. This advanced functionality eliminates the need for secondary operations, drastically improving efficiency.

Additionally, operators can make on-the-fly adjustments to improve precision or accommodate new designs, making CNC lathes incredibly flexible for prototyping and mass production alike.

6. User-Friendly Interface and Safety

Despite their complexity, CNC lathes are designed with user-friendly interfaces that make them accessible even for operators with minimal experience. Touchscreen controls, intuitive software, and real-time monitoring systems make it easy to oversee operations and make adjustments when necessary.

Moreover, CNC lathes come with built-in safety features that reduce the risk of accidents. Enclosed workspaces, automatic shutoffs, and sensor-driven feedback systems ensure that operators are protected during the machining process. This makes CNC lathes not only highly efficient but also safe to use.

7. Why Choose CNC Lathes for Your Manufacturing Needs?

When it comes to precision machining, CNC lathes offer unmatched benefits that elevate production capabilities to the next level. Here’s a quick rundown of why CNC lathes are the go-to solution for industries worldwide:

Unmatched Precision: Micron-level accuracy ensures high-quality parts every time.

Efficient Automation: Reduce downtime and increase output with automated processes.

Versatility: Suitable for a wide range of materials and industries.

Advanced Technology: CAD/CAM integration and multi-axis control offer incredible flexibility.

Safety and Ease of Use: Designed with operator safety and user-friendly interfaces in mind.

CNC lathes are ideal for businesses seeking to streamline their production processes, increase precision, and reduce costs over time. Their ability to handle both complex designs and high-volume manufacturing makes them a cornerstone of modern machining.

Conclusion

CNC lathes represent the cutting-edge technology of precision machining, offering unparalleled accuracy, efficiency, and versatility. Whether you're producing intricate one-off components or running large production batches, these machines deliver consistently high-quality results. With their ability to work across multiple industries and materials, CNC lathes are an essential tool in today’s manufacturing landscape, blending advanced automation with human ingenuity.

If you’re looking to enhance your production capabilities and achieve superior results, investing in a CNC lathe is a step toward innovation and excellence.