- Time:2024/10/24 Posted:Dongguan Quality Innovation And Technology Co.,Ltd

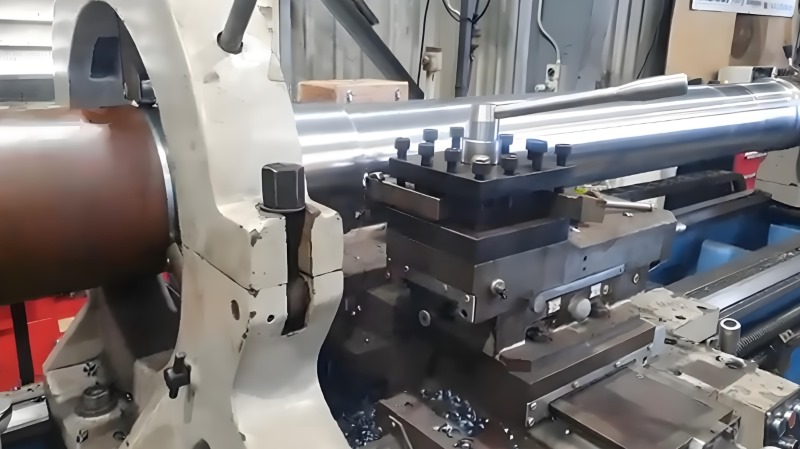

CNC lathes are a game-changer for industries that require precision, speed, and reliability in manufacturing. From the automotive and aerospace sectors to custom part production, CNC lathes offer an unmatched level of efficiency, accuracy, and flexibility. Whether you're producing high-precision engine components or creating custom parts for specialized applications, CNC lathes are the ideal solution.

In this blog, we will explore the key features, benefits, and applications of CNC lathes, highlighting why they have become indispensable in modern manufacturing and how they can elevate your production capabilities.

1. Precision and Accuracy for High-Performance Industries

In industries like automotive and aerospace, where even the slightest error can result in significant losses, precision is paramount. CNC lathes are designed to deliver consistent, accurate results with tight tolerances, ensuring that each part produced meets the exact specifications required.

Key Features:

Micron-Level Precision: CNC lathes can achieve sub-millimeter accuracy, making them ideal for producing high-precision parts like engine components, aerospace fittings, and other critical components that must adhere to strict standards.

Consistent Quality: With CNC automation, every part produced is identical to the last, ensuring uniformity across batches. This level of consistency is especially important for industries that demand high-performance and reliability in every component.

Error Minimization: CNC lathes reduce the risk of human error, thanks to their fully automated processes. Operators can rely on the machine’s programming to maintain precision throughout the production run, minimizing costly mistakes.

For industries that demand high-quality, precision-made components, CNC lathes provide an unrivaled level of accuracy and reliability.

2. Speed and Efficiency for Large-Scale Production

Time is money in manufacturing, and CNC lathes are built to maximize production speed without sacrificing quality. The automated nature of CNC lathes means they can run continuously with minimal downtime, allowing for high-volume production in a short time.

Key Features:

High-Speed Machining: CNC lathes can operate at extremely high speeds, reducing production times for even the most complex parts. This is crucial for industries like automotive, where fast turnaround times are essential to meet demand.

Continuous Operation: CNC lathes can run 24/7, making them perfect for large-scale production environments. Automated machining allows manufacturers to meet tight deadlines while maintaining high output levels.

Multi-Tasking Capabilities: Modern CNC lathes are capable of performing multiple operations such as turning, drilling, and milling in a single setup. This minimizes the need for machine changeovers, further speeding up production.

For manufacturers who need to meet high production quotas without sacrificing quality, CNC lathes offer the speed and efficiency required to stay competitive.

3. Versatility for Custom Part Production

While CNC lathes are known for high-volume production, they are equally valuable for custom part manufacturing. Their programmable nature allows for quick changes between designs, making them perfect for one-off custom parts or small production runs tailored to specific needs.

Key Features:

Flexible Programming: With CNC lathes, custom parts can be produced by simply uploading a new design program. This flexibility makes it easy to switch between different parts, even in the middle of a production cycle.

Complex Geometries: CNC lathes can handle the production of complex shapes and intricate geometries that would be challenging or impossible to achieve using traditional methods. This makes them ideal for custom components in industries like aerospace and medical devices.

Quick Prototyping: CNC lathes are perfect for rapid prototyping, allowing manufacturers to quickly produce and test custom designs before moving into full-scale production. This speeds up the innovation process and enables faster development of new products.

For industries that require custom parts or specialized components, CNC lathes offer the versatility needed to meet diverse manufacturing demands.

4. Durability and Longevity for Tough Industrial Environments

CNC lathes are built to withstand the rigors of industrial production. Constructed from durable materials and equipped with advanced cooling systems, they are designed to handle high workloads while maintaining optimal performance.

Key Features:

Rugged Construction: CNC lathes are made from high-quality materials that ensure durability and long service life, even in tough industrial settings. This makes them ideal for industries like aerospace, where machines must operate under demanding conditions.

Advanced Cooling Systems: To prevent overheating during long production runs, CNC lathes are equipped with sophisticated cooling mechanisms that keep the machine running smoothly and efficiently.

Minimal Wear and Tear: The automated, contactless nature of CNC machining results in minimal wear and tear on the machine itself, ensuring that CNC lathes require less maintenance and have a longer lifespan compared to traditional lathes.

This durability makes CNC lathes a long-term investment for manufacturers looking for reliable machines that can handle continuous use without frequent breakdowns or maintenance issues.

5. Automation and Reduced Labor Costs

One of the most significant advantages of CNC lathes is their ability to automate the manufacturing process, reducing the need for manual labor. This not only cuts labor costs but also reduces the risk of human error, leading to higher efficiency and better-quality output.

Key Features:

Fully Automated Machining: Once programmed, CNC lathes can run independently with minimal supervision. This frees up operators to focus on other tasks, improving overall productivity.

Reduced Setup Times: CNC lathes are designed to minimize setup times between jobs, allowing for quicker production changes and shorter lead times.

Lower Labor Costs: By automating much of the machining process, CNC lathes reduce the need for a large workforce, leading to significant cost savings over time.

For businesses looking to improve operational efficiency and reduce costs, CNC lathes offer a compelling solution by streamlining production processes and minimizing labor requirements.

6. Perfect for Automotive, Aerospace, and More

CNC lathes are versatile enough to be used across a wide range of industries, but they are particularly well-suited for sectors like automotive, aerospace, and custom part production. These industries demand the highest levels of precision, speed, and reliability, all of which CNC lathes are built to deliver.

Automotive Applications:

In the automotive industry, CNC lathes are used to produce a wide variety of components, from engine parts to brake discs. The precision and consistency of CNC machining ensure that these critical components meet strict quality standards, contributing to the safety and performance of vehicles.

Aerospace Applications:

Aerospace components often have complex geometries and require exceptionally tight tolerances. CNC lathes are capable of producing parts with the precision and consistency necessary for aircraft engines, landing gear, and other vital systems.

Custom Part Production:

For industries that require unique, made-to-order components, CNC lathes are the perfect solution. Whether it's a small batch of custom parts or a prototype for a new product, CNC lathes can quickly and accurately produce the necessary components.

Conclusion

CNC lathes are an essential tool in modern manufacturing, providing unmatched precision, speed, and versatility for a wide range of industries. From automotive and aerospace to custom part production, these machines deliver high-quality results that meet the demands of even the most challenging applications.

With their ability to produce complex geometries, handle large-scale production, and minimize labor costs, CNC lathes are an investment that pays off in both the short and long term. Whether you're a manufacturer looking to streamline your production processes or an industry professional seeking the highest level of precision, CNC lathes offer the ideal solution for your manufacturing needs.