- Time:2024/12/28 Posted:Dongguan Quality Innovation And Technology Co.,Ltd

Aluminum profile casting is a manufacturing process that involves pouring molten aluminum into a mold to create a solid object. The resulting object, called an aluminum profile, can be used in a variety of applications, including automotive parts.

Process characteristics of aluminum profile casting

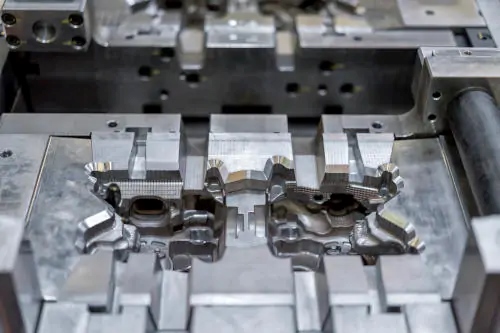

Aluminum profile casting is a complex process that involves several steps. First, the aluminum is melted in a furnace. The molten aluminum is then poured into a mold. The mold is made of a material that can withstand the high temperatures of the molten aluminum. Once the aluminum has cooled and solidified, the mold is opened and the aluminum profile is removed.

Aluminum profile casting has several advantages over other casting processes. First, it is a relatively fast process. Second, it can produce complex shapes with high accuracy. Third, aluminum is a lightweight metal, which makes it ideal for use in automotive parts.

Application of different alloys in aluminum profile casting

Different alloys of aluminum are used in different applications of aluminum profile casting. The choice of alloy depends on the properties required for the application. For example, some alloys are more resistant to corrosion, while others are more resistant to wear.

Some of the most common alloys used in aluminum profile casting for automotive parts include:

AlSi9Mg: This alloy is a good choice for applications that require high strength and good corrosion resistance.

AlMg3: This alloy is a good choice for applications that require high strength and good formability.

AlZnMgCu: This alloy is a good choice for applications that require high strength and good weldability.

Future development trends of aluminum profile casting

Aluminum profile casting is a mature technology that is constantly evolving. Some of the future development trends of aluminum profile casting include:

Higher precision: Aluminum profile casting is becoming increasingly precise. This is due to advances in technology, such as the use of computer-aided design (CAD) and computer-aided manufacturing (CAM).

Thinner profiles: Aluminum profile casting is being used to produce thinner profiles. This is due to the development of new casting techniques and the use of stronger alloys.

More complex shapes: Aluminum profile casting is being used to produce more complex shapes. This is due to the development of new casting techniques and the use of more sophisticated molds.

Role of aluminum profile casting in energy conservation and emission reduction

Aluminum profile casting plays an important role in energy conservation and emission reduction. This is because aluminum is a lightweight metal, which means that vehicles made with aluminum parts are more fuel-efficient. In addition, aluminum profile casting is a relatively energy-efficient process.

Conclusion

Aluminum profile casting is a versatile and important manufacturing process that is used in a variety of applications, including automotive parts. It is a complex process that involves several steps, but it can produce high-quality parts with a variety of properties. Aluminum profile casting is a mature technology that is constantly evolving. In the future, we can expect to see even more innovative applications of aluminum profile casting in the automotive industry.