- Time:2025/04/10 Posted:Dongguan Quality Innovation And Technology Co.,Ltd

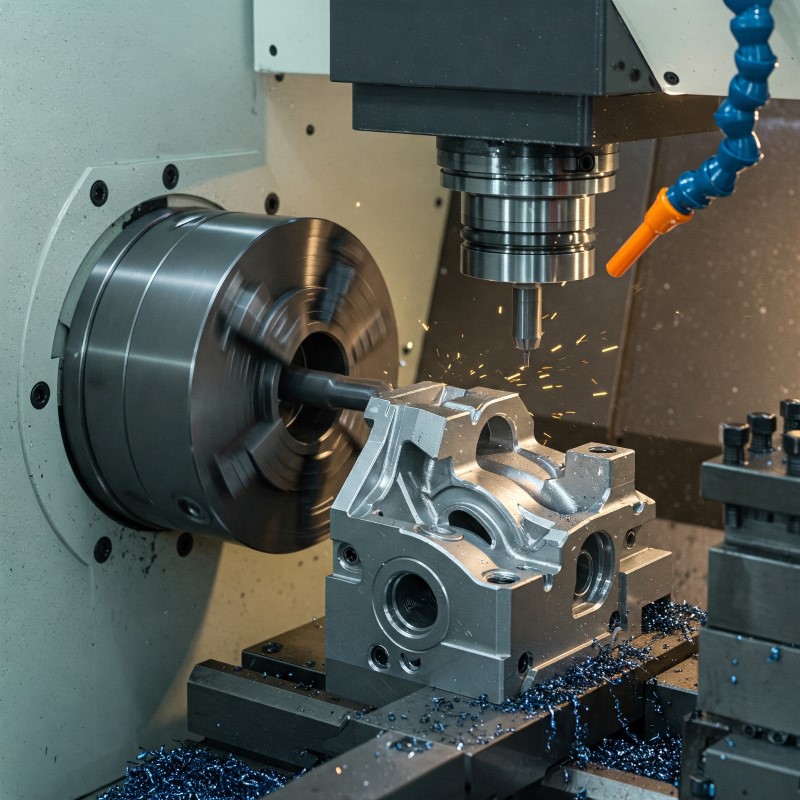

In modern manufacturing, CNC lathe machining plays a crucial role in producing high-precision parts for industries such as automotive, aerospace, electronics, and medical equipment. This case study showcases how one CNC machining provider successfully delivered cost-effective, high-quality custom parts under tight deadlines—highlighting the power of advanced machining, excellent cost-performance, and large-scale efficiency.

Client Challenge: High Precision, Tight Budget, Fast Delivery

A European client in the robotics industry needed a batch of custom aluminum shafts with tight tolerances, smooth surface finishes, and consistent quality. They were on a deadline and had limited budget flexibility. Previous suppliers either overcharged or failed to meet the necessary quality standards.

Our Solution: CNC Lathe Machining with Smart Cost Control

The machining team used high-speed CNC lathe equipment to deliver parts with superior precision. Here’s how we optimized the process:

Precision CNC Lathes – Capable of achieving tolerances within ±0.01 mm, ensuring perfect fit and performance.

Optimized Programming – Advanced CAM software reduced cycle time and minimized material waste.

Material Efficiency – By sourcing cost-effective aluminum stock in bulk, material costs were significantly reduced.

Batch Production – Parts were machined in large volumes with automated systems, improving speed and consistency.

Results: Cost Savings + Market Success

Parts delivered 3 days ahead of schedule

Parts delivered 3 days ahead of schedule Client saved over 25% compared to previous supplier

Client saved over 25% compared to previous supplier Zero rework rate after quality inspection

Zero rework rate after quality inspection Product became a best-seller in their assembly line offering

Product became a best-seller in their assembly line offeringThis case proves that top-tier CNC lathe machining doesn’t have to come at a premium—with the right technology and production strategy, businesses can enjoy both quality and affordability.

Conclusion

CNC lathe machining offers unmatched versatility and precision for custom metal and plastic parts. With the lowest pricing, efficient workflows, and high-quality results, it’s no surprise that CNC-turned components are in high demand worldwide.

Want to learn more or request a custom quote? Contact us today and discover how our CNC lathe machining services can maximize performance without exceeding your budget.