- Time:2024/07/27 Posted:Dongguan Quality Innovation And Technology Co.,Ltd

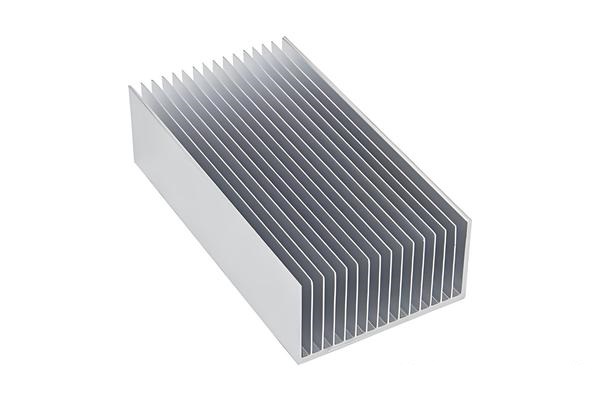

Features of aluminum profile radiator: The distance between the fins is short, and a groove is formed between two adjacent fins. Its depth-to-width ratio is large; the wall thickness difference is large. Generally, the fins are thin, and the base of the base is large. Aluminum profile radiators are - some products with small size and symmetrical shape are easier to produce, most radiator profiles are flat, with large external dimensions, and some are asymmetrical. The depth-to-width ratio of the groove between the fins is large, and its production is difficult. It is necessary to cooperate in the ingot casting and mold extrusion process to successfully produce aluminum profile radiators.

What are the requirements for aluminum alloy used in aluminum alloy radiators?

The alloy used for extruded radiator profiles must have good extrudability and thermal conductivity. At present, 6061 aluminum alloy and 6063 aluminum alloy are commonly used. 6063 alloy is more common because it has good extrudability and thermal conductivity, as well as good mechanical properties. Does aluminum alloy have good heat dissipation performance? Aluminum alloy radiators have good oxidation and corrosion resistance and good environmental adaptability; they have a long service life and are relatively inexpensive. The most important thing is that they have very good heat dissipation effect during use. Aluminum alloy radiators are widely used in industries such as mechanical vehicle batteries, wind power generation, engineering machinery, air compressors, railway locomotives, and household appliances due to their superior performance.

Aluminum profile radiator production requirements: The production of aluminum profile radiators should start from the quality of ingots, the material and design of molds, reducing extrusion force and extrusion process. In addition to the above factors, extrusion technology is also related to the capacity and level of the extruder, the degree of automation of the rear equipment, and the operating skills of people. Different aluminum profile radiator cross-sections should adopt corresponding extrusion process flows according to specific conditions.

Is the thicker the aluminum profile radiator, the better?

Usually, ordinary consumers have such a consumption concept: the larger the volume of the item, the better, the more the quantity, the better, and the more materials, the better, because the more sufficient the materials, the higher the price and the better the quality. When purchasing aluminum profile radiators, it is taken for granted that the thicker the wall thickness of the aluminum profile radiator, the better the product quality, but this is not the case. The technician said: The standard for the wall thickness of aluminum profile radiators is set according to the actual heat dissipation requirements and energy-saving and environmental protection requirements, and the thicker the product wall thickness, the better the product quality, and the thicker the wall thickness of the aluminum profile radiator, the heavier the raw materials used. According to the current price of raw materials, the cost of producing aluminum profile radiators is higher. Because the heat dissipation effect is proportional to the wind-receiving surface and inversely proportional to the degree of enjoyment. Too thick profile wall thickness cannot guarantee good heat dissipation effect and high product quality, but will bring excessive waste of resources. Too thick products consume more materials, which will inevitably bring too high product prices and bring unnecessary economic burdens to consumers. Therefore, aluminum profile radiator products that meet actual needs can be called good products.

How to identify and distinguish high-tooth aluminum profile radiators from ordinary aluminum profile radiators?

The following simple method is summarized by the world of mold teaching for your reference:

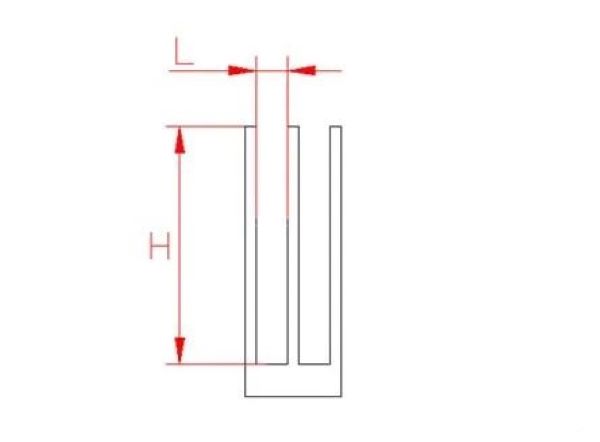

1. High-tooth radiators refer to those with relatively more teeth and higher tooth height. The usual identification standard is the ratio of tooth height to tooth pitch, as shown in the figure below. The formula is: tooth height (H) / tooth pitch (L), that is: K=H/L. The calculated K value is greater than 8. This is generally called a high-tooth aluminum profile radiator.

2. According to the above calculation method, the aluminum profile radiator with a calculated K value less than 8 is considered an ordinary aluminum profile radiator.

The method introduced above is the most common and practical method. Through this method, it can be determined whether the designed aluminum profile radiator can be developed. Generally speaking, the higher the teeth, the higher the requirements for the aluminum profile extrusion die used, the greater the difficulty, and the higher the price, because this requires higher toughness of the mold material and the rationality of the mold design.