- Time:2025/04/27 Posted:Dongguan Quality Innovation And Technology Co.,Ltd

In the world of precision manufacturing, aluminum CNC turning stands out as a highly versatile and reliable method for producing parts that are both lightweight and strong. Whether for aerospace, automotive, medical, or industrial applications, aluminum has earned its reputation as the material of choice for products that require high strength-to-weight ratios. The integration of CNC (Computer Numerical Control) technology in aluminum turning has further enhanced its utility by allowing manufacturers to create complex, precise components with unparalleled accuracy.

Aluminum’s unique properties, combined with the capabilities of CNC turning, make it a go-to solution for a variety of demanding industries. Here’s why aluminum CNC turning is essential for modern manufacturing.

What is Aluminum CNC Turning?

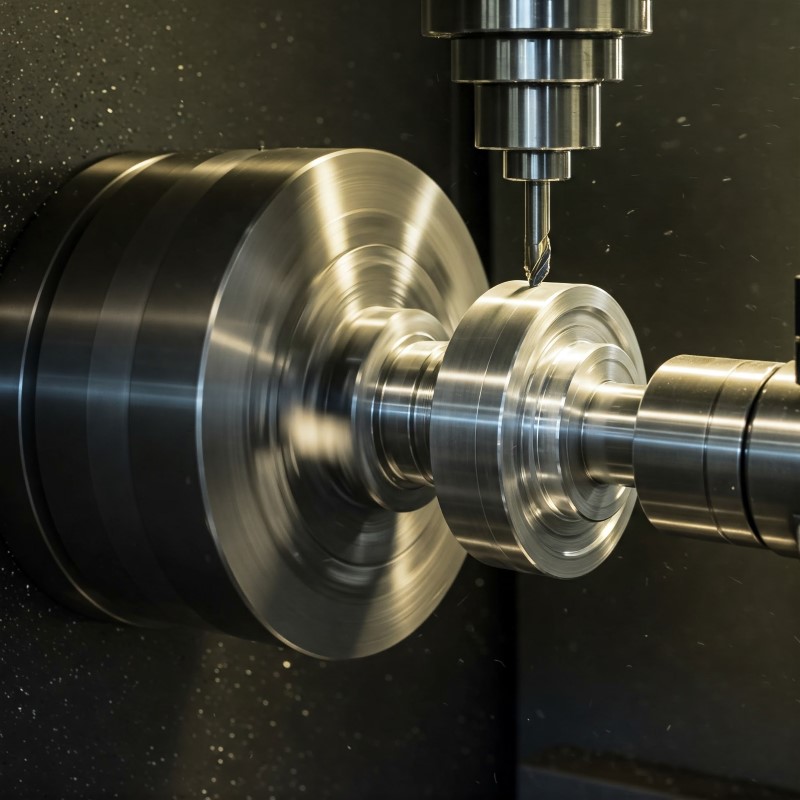

CNC turning is a computer-controlled machining process where a cylindrical piece of material, in this case, aluminum, is rotated on a lathe while a cutting tool removes material to shape the part. This process is highly precise, offering the ability to create complex geometries, smooth finishes, and tight tolerances.

Aluminum CNC turning is particularly favored because of aluminum’s characteristics:

Lightweight: Aluminum is significantly lighter than other metals like steel, making it ideal for applications where weight is a concern.

Strength: Despite being lightweight, aluminum has excellent strength, making it suitable for high-stress environments.

Corrosion Resistance: Aluminum is naturally resistant to corrosion, which is essential for applications exposed to harsh conditions or the elements.

Machinability: Aluminum is easier to machine than many metals, which reduces manufacturing time and costs.

Key Benefits of Aluminum CNC Turning

Precision and Accuracy

CNC turning allows for highly precise and repeatable results, ensuring that each part meets the exact specifications required for your application. The computer-controlled machinery guarantees that parts are manufactured to tight tolerances—a critical feature for industries like aerospace or automotive, where precision is paramount.

Strength-to-Weight Ratio

One of the main reasons why aluminum is so popular in manufacturing is its high strength-to-weight ratio. Parts made from aluminum are not only light but also durable and can withstand demanding mechanical loads. This makes aluminum CNC turning the ideal solution for applications such as aircraft components, automotive parts, and structural elements in construction.

Versatility Across Industries

Aluminum CNC turning is used in a wide range of industries, including:

Aerospace: Parts like engine components, frames, and landing gear.

Automotive: Wheels, engine blocks, and transmission parts.

Medical: Surgical instruments, prosthetics, and medical device housings.

Electronics: Housings for laptops, smartphones, and other electronic devices.

Cost-Effective and Efficient

Aluminum is not only lightweight and strong but also cost-effective compared to many other metals. Combined with the efficiency of CNC turning, which automates the process, aluminum CNC turning offers a highly cost-effective manufacturing solution, especially for high-volume production runs.

Customizability

Aluminum CNC turning allows manufacturers to create custom designs with intricate features, including detailed threads, grooves, and holes. Whether you need standard parts or highly specialized components, CNC turning offers the flexibility to meet your needs.

Applications of Aluminum CNC Turning

Aerospace Components: Aircraft require lightweight yet strong parts, such as structural components, brackets, and engine parts, which are often made from aluminum.

Automotive Parts: Aluminum CNC turning is used to create engine components, wheels, and transmission parts, all of which benefit from the material’s strength-to-weight ratio.

Medical Devices: Precision machined aluminum parts are used in surgical instruments, prosthetics, and medical devices, ensuring both durability and biocompatibility.

Electronics: Aluminum CNC turning is widely used to create enclosures for laptops, phones, and other electronic devices, offering a sleek, lightweight design.

Why Choose Quality Manufacturer?

At Quality Manufacturer, we specialize in aluminum CNC turning to produce high-performance, custom-machined parts for a variety of industries. Our advanced CNC machining technology, paired with our expert team, ensures that each component is manufactured to the highest standards of quality, precision, and durability.

Here’s why businesses trust Quality Manufacturer for their CNC turning needs:

Advanced CNC Technology: We use state-of-the-art CNC machines that offer high precision, repeatability, and the ability to work with complex geometries.

Customization and Flexibility: Whether you need small batches or large-scale production, we offer tailored solutions for your unique manufacturing needs.

Industry Expertise: Our team has extensive experience working across a range of industries, including aerospace, automotive, medical, and electronics.

Prototyping and Design Support: We offer design consultation and prototyping services to help bring your ideas to life.

Precision and Quality Control: Each part undergoes rigorous inspection and testing to ensure it meets the tightest tolerances and industry standards.

Cost-Effective Solutions: With a focus on efficiency and quality, we provide cost-effective solutions for both small and large production runs, ensuring maximum value for your investment.

Need precision-machined aluminum parts for your next project?

Choose Quality Manufacturer — your trusted partner in CNC turning and custom manufacturing solutions.Have a custom request or need more information?

Contact us today — and let us help you create the perfect components for your needs.