- Time:2025/05/14 Posted:Dongguan Quality Innovation And Technology Co.,Ltd

Aluminum die casting has become a pivotal manufacturing process for various industries, offering a wide range of benefits from strength and durability to lightweight performance. The versatility of aluminum die casting solutions makes it an ideal choice for industries like automotive, electronics, aerospace, and more. In this article, we will explore how aluminum die casting is transforming these sectors and why it is becoming an indispensable manufacturing solution.

Automotive Industry: Lightweight & Durable Components

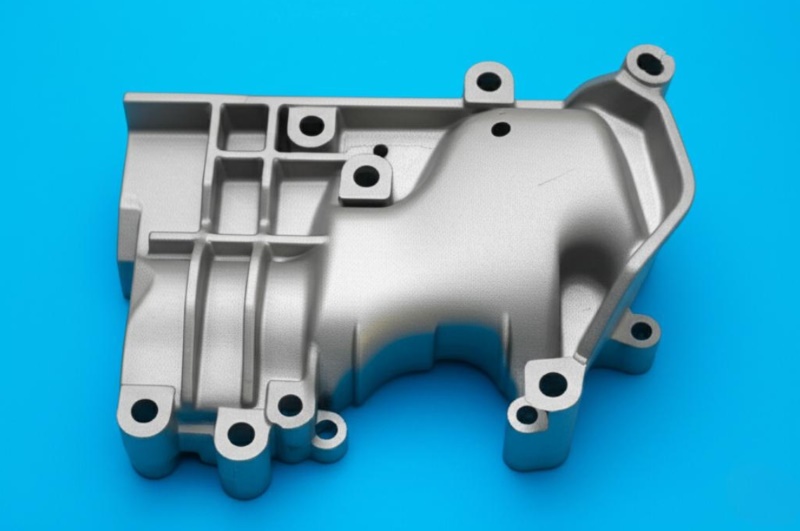

In the automotive industry, aluminum die casting is revolutionizing vehicle manufacturing. With increasing demand for fuel efficiency and environmental sustainability, lightweight materials are a priority for car manufacturers. Aluminum is the perfect solution, providing exceptional strength-to-weight ratios while reducing the overall weight of vehicles.

Key automotive components, including engine blocks, transmission housings, and structural parts, benefit from aluminum die casting's ability to create complex, precise, and robust parts. The durability of aluminum also contributes to the longevity and performance of the vehicle, making it a preferred choice for high-performance cars and electric vehicles (EVs).

Electronics Industry: Precision and Heat Dissipation

The electronics industry also reaps the benefits of aluminum die casting, particularly when it comes to producing components that require both precision and efficient heat dissipation. Electronic devices, from smartphones and laptops to LED lighting and power electronics, demand parts that are both lightweight and able to withstand high temperatures.

Aluminum die casting allows for the creation of intricate designs with fine details, ensuring that components fit seamlessly in tight spaces. Additionally, aluminum's natural ability to dissipate heat makes it an ideal material for electronic casings and heat sinks, ensuring that devices remain cool and operate efficiently even under intense usage.

Aerospace: Strength and Reliability

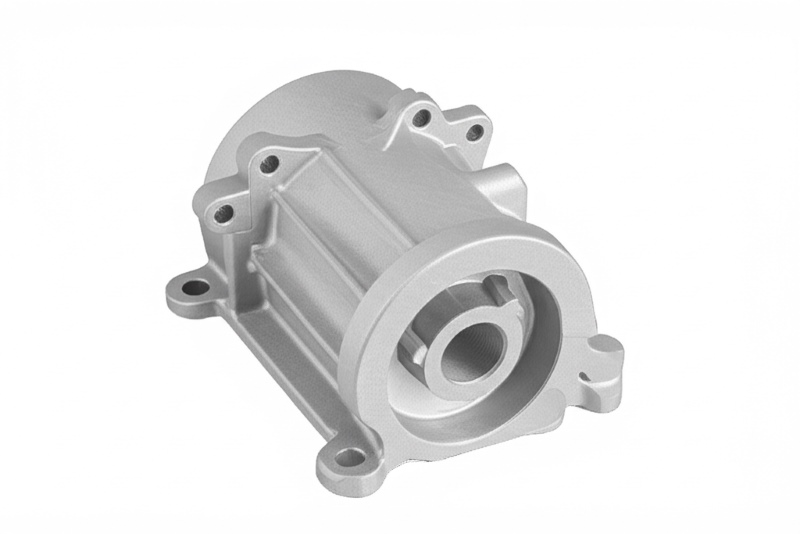

The aerospace industry, which requires materials that are both lightweight and extremely durable, is another sector where aluminum die casting plays a crucial role. Components such as turbine housings, frames, and wing supports must endure extreme temperatures and pressures. Aluminum, with its ability to be molded into complex shapes while maintaining strength, is a key material in this high-stakes industry.

Die casting provides aerospace manufacturers with the ability to produce components that meet stringent tolerances and performance standards. Additionally, the ability to reduce the number of parts by combining them into a single die-cast piece can lower production costs and increase efficiency.

Why Choose Quality Group?

At Quality Group, we specialize in providing high-quality aluminum die casting solutions that cater to a wide range of industries, from automotive to electronics. Our commitment to precision, innovation, and sustainability ensures that each product we deliver exceeds our clients' expectations. With years of experience and a focus on advanced technology, we offer reliable and cost-effective die-casting services that can help your business thrive.

Whether you’re looking to enhance your product’s performance, reduce weight, or improve production efficiency, Quality Group is the trusted partner you can rely on.

Need more information? Contact us today!