- Time:2025/05/22 Posted:Dongguan Quality Innovation And Technology Co.,Ltd

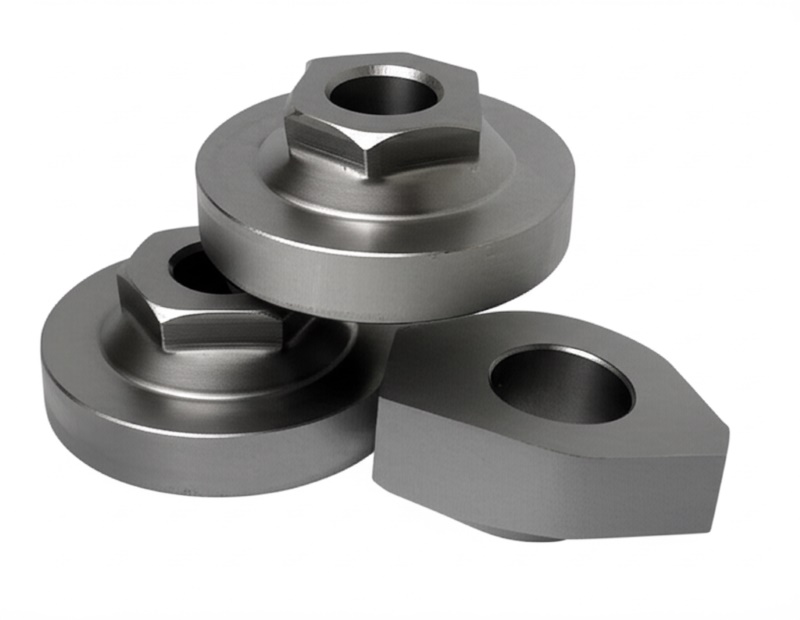

Cold Forged Parts: Engineered for Strength and Precision

Cold Forged Parts are the foundation of strength and reliability in modern manufacturing. Created by compressing metal at room temperature, these components offer superior structural integrity, making them ideal for high-stress applications across various industries.

Automotive Applications: Built to Perform

In the automotive sector, Cold Forged Parts are widely used in drivetrain components, steering systems, and fasteners. Their high tensile strength and dimensional accuracy ensure durability under constant stress—crucial for both performance and safety in vehicles.

Aerospace & Defense: Light but Mighty

Weight and strength are critical in aerospace. Cold forging enables the creation of lightweight yet robust parts such as gear blanks, brackets, and fasteners. These components can withstand extreme pressure and vibration without compromising integrity.

Industrial Machinery: Dependable Under Load

In heavy-duty equipment and industrial machines, Cold Forged Parts are used in gears, shafts, and bearings. Their ability to resist deformation under repeated use ensures long service life with minimal maintenance—key for reducing operational downtime.

Why Cold Forging?

Cold forging improves metal grain structure, resulting in parts that are stronger and more wear-resistant. It also reduces waste and energy consumption, making it an environmentally responsible choice for high-volume production.

Why Choose Quality Group?

At Quality Group, we specialize in precision-engineered Cold Forged Parts that meet the highest industry standards. Our advanced processes, skilled team, and strict quality control deliver parts that perform under the most demanding conditions.

Need high-performance cold-forged solutions?

Please contact us today.