- Time:2025/05/22 Posted:Dongguan Quality Innovation And Technology Co.,Ltd

Cold Forging: A Modern Approach to Metal Strength

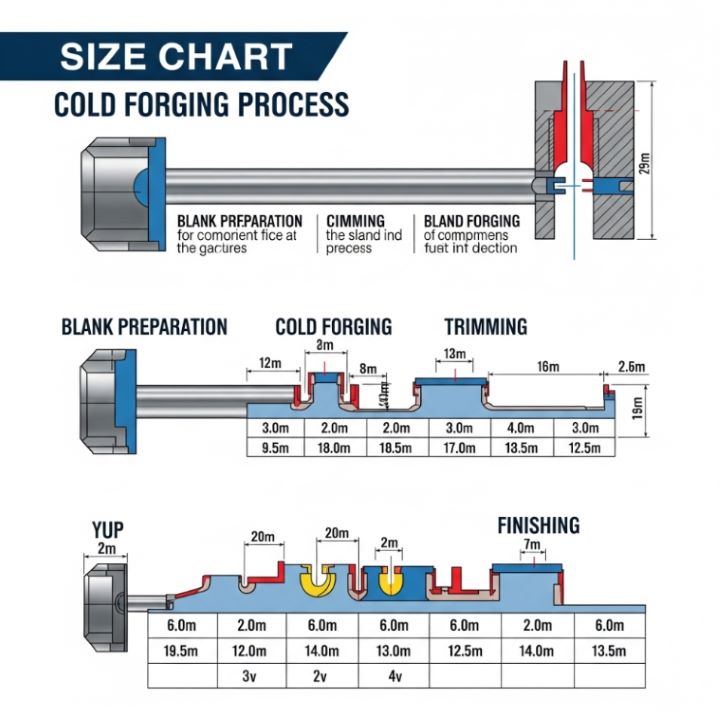

Cold forging is a precision metal-forming technique where raw material is shaped at room temperature using high pressure. Unlike traditional hot processes, it enhances part strength, surface finish, and dimensional accuracy—making it a preferred choice in many advanced manufacturing sectors.

How Cold Forging Works

Cold forging involves compressing metal—usually steel or aluminum—into a die without heating it beyond recrystallization. This preserves material integrity, reduces oxidation, and results in a refined grain structure that improves mechanical performance.

Industries That Rely on Cold Forging

From automotive to aerospace, cold forging is used to manufacture shafts, fasteners, gears, and bearings. In automotive systems, for instance, it ensures stronger and lighter components for fuel efficiency and safety. In electronics, it helps create compact, precise parts with minimal waste.

Benefits Beyond Strength

The benefits of cold forging go beyond durability. It allows for high-volume production with minimal machining, reducing both cost and environmental impact. Its near-net-shape capabilities also mean fewer defects and better consistency across parts.

Precision in Every Press

As industries demand tighter tolerances and better surface finishes, cold forging stands out for its ability to deliver both. It’s a process that transforms raw metal into robust, high-performance components—efficiently and sustainably.

Why Choose Quality Group?

At Quality Group, we bring decades of engineering expertise to the field of cold forging. Our advanced equipment, strict quality standards, and customized solutions ensure each part meets your exact specifications.

Have a project in mind or need expert guidance?

Please contact us today.