LED light heat sinkCurrent location : Home > Products > Heat sink > LED light heat sink

Basic Info.

Model NO.

QH-160605-BL0001

Sample Lead Time

3-5 Working Days

Torlerance

+-0.005mm

Capacity

100000 PCS Per Month

Terms

Fob,CIF,CFR

Processing

CNC Machining,CNC Turning,Drilling,Milling,Brushin

Application

Electronic Harware Accessories,Heat Sinks,Radiator

Raw Material

Aluminum Alloy,Stainless Steel,Copper

Transport Package

Foam+Paper Cartons+Wooden Pallet

Specification

OEM(According to cleint′s design

Trademark

NO

Origin

Made in China

HS Code

94059900

Production Capacity

100000 PCS Per Month

Product Description

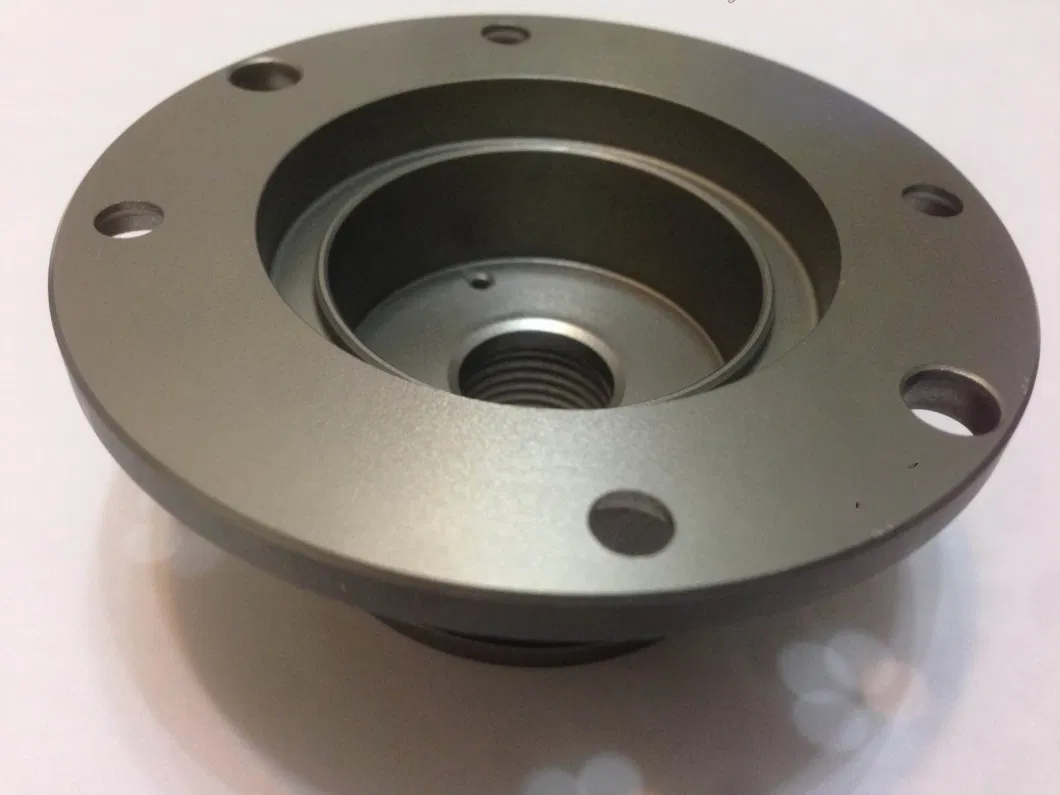

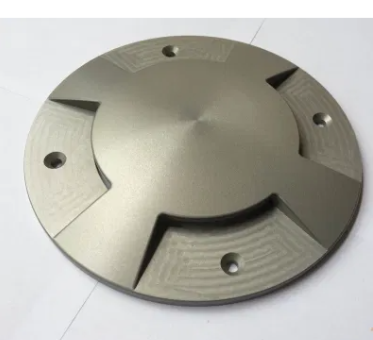

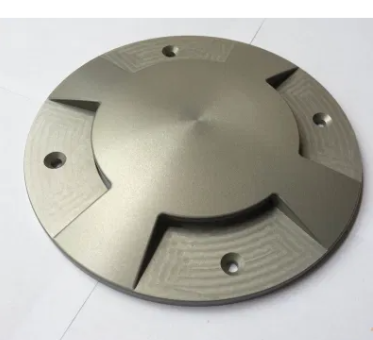

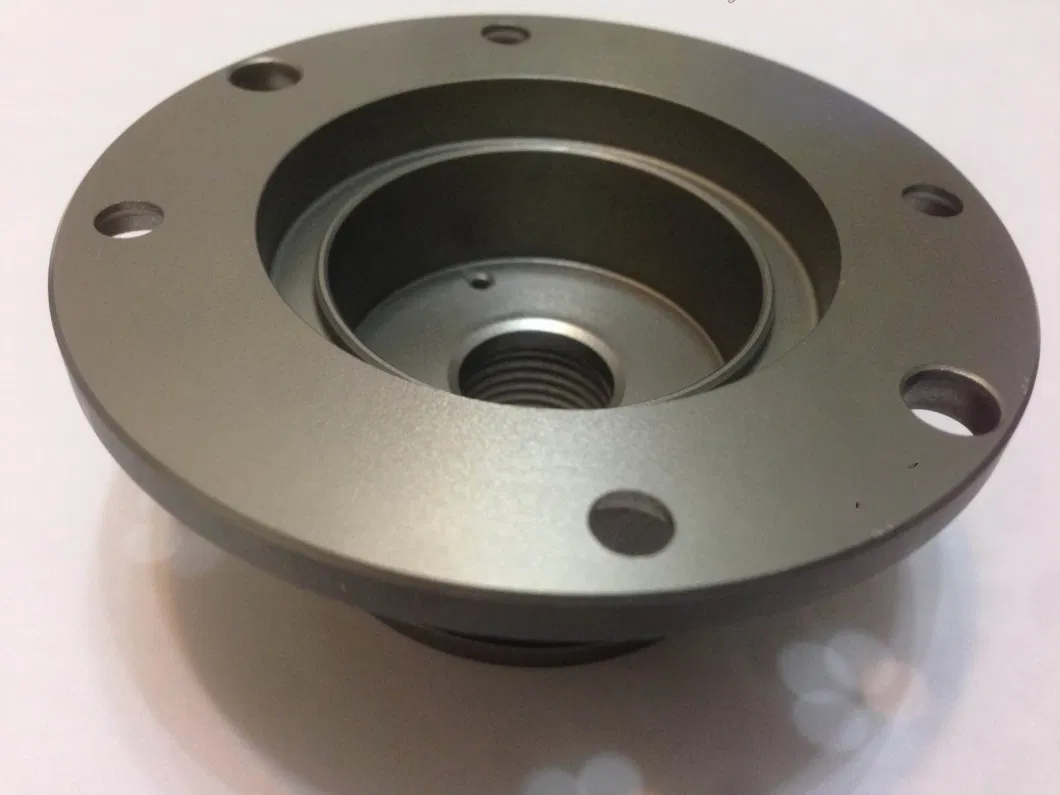

Item:High Precision CNC Machinery Hard Anodized Aluminum heat sinks LED inground lighting aluminum turning milling heat sinks

Function:

Heat sink is a device for radiating easily heated electronic components in electrical

appliances. It is mostly made of aluminum alloy, brass or bronze, plate, sheet, multi

sheet, etc. its main function is to dissipate heat.

Kinds of heat sink

1. According to the processing method, there are finger radiator, profile radiator

(extruded into profile), insert radiator, casting radiator, etc.

2. According to the

cooling method, there are natural cooling radiator, air cooling radiator, liquid cooling

radiator (water cooling radiator, oil cooling radiator), cold plate radiator, heat pipe

radiator, etc.

3. According to professional purposes: Heat Dissipation Calculation of

power devices and selection of radiators. Electronic products with electronic heat sinks

mainly use patch packaging devices, but many high-power devices and some power modules

still use perforated packaging, which can be easily installed on the radiator for heat

dissipation.

4. According to the materials used: aluminum radiator, copper radiator and

steel radiator.

5. According to the power used: there are low-power radiator, medium

power radiator and high-power radiator.

6. According to the characteristics of radiator

Standard of heat sink

1. The quality of material (purity, thickness, processing accuracy, etc.) and

manufacturing process (cracks, shrinkage cavities, etc. caused by casting), poor

material and rough and defective process will directly affect the thermal conductivity

of the radiator;

2. The surface roughness and flatness of the electronic heat sink

contact table directly affect the contact thermal resistance and pressure drop;

Parameter :

Our advantage:

1. Experienced engineering team;

2. Full process QC inspection, complete quality system before, during and after processing;

3. Efficient and rapid response, benign interaction between business and production, and accurately grasp customer requirements;

Function:

Heat sink is a device for radiating easily heated electronic components in electrical

appliances. It is mostly made of aluminum alloy, brass or bronze, plate, sheet, multi

sheet, etc. its main function is to dissipate heat.

Kinds of heat sink

1. According to the processing method, there are finger radiator, profile radiator

(extruded into profile), insert radiator, casting radiator, etc.

2. According to the

cooling method, there are natural cooling radiator, air cooling radiator, liquid cooling

radiator (water cooling radiator, oil cooling radiator), cold plate radiator, heat pipe

radiator, etc.

3. According to professional purposes: Heat Dissipation Calculation of

power devices and selection of radiators. Electronic products with electronic heat sinks

mainly use patch packaging devices, but many high-power devices and some power modules

still use perforated packaging, which can be easily installed on the radiator for heat

dissipation.

4. According to the materials used: aluminum radiator, copper radiator and

steel radiator.

5. According to the power used: there are low-power radiator, medium

power radiator and high-power radiator.

6. According to the characteristics of radiator

Standard of heat sink

1. The quality of material (purity, thickness, processing accuracy, etc.) and

manufacturing process (cracks, shrinkage cavities, etc. caused by casting), poor

material and rough and defective process will directly affect the thermal conductivity

of the radiator;

2. The surface roughness and flatness of the electronic heat sink

contact table directly affect the contact thermal resistance and pressure drop;

Parameter :

| Item | High Precision CNC Machinery Hard Anodized Aluminum heat sinks LED inground lighting aluminum turning milling heat sinks |

| Weight | Customized |

| Dimension | Customized |

| Material | Aluminum alloy(6063 T5,6061,5052,7075,1060...),Stainless steel(316L,304,303...),Copper,Brass,Bronze |

| Machined Technology | 3,4,5 Axis CNC Machining,CNC Milling,CNC Turning,Laser Cutting,Die Casting,Cold forging,Aluminum Extrusion,Sheet Metal Fabrication,Stamping,Welding,Friction Stir Welding,Assembling. |

| Surface Treatment | Anodizing,Painting,Powder Coating,electrophoresis,Passivation,Sand Blasting,Plating,Blackening,Polishing... |

| Tolerance | ±0.01MM |

| Application | Electronic products body ,Telecom Chasis,Cover,aerospace structure parts,heat sink,aluminum cooling plate,gear&shaft,bearing,high speed feed through,other OEM/ODM customized machining parts,screw,nut,bolt,stud,other fastener and fitting parts |

Our advantage:

1. Experienced engineering team;

2. Full process QC inspection, complete quality system before, during and after processing;

3. Efficient and rapid response, benign interaction between business and production, and accurately grasp customer requirements;